Our technological growth is a palpable reality. The development of software that personalizes HVAC control needs of our clients is already a fact. Dynamiq’s Department of Technological Development and Innovation Specialists are driving unprecedented growth with codes and algorithms. Undoubtedly, this is great news for our community. Today, we share the details of Dynamiq’s software for Automated HVAC Solutions.

The need to maintain high standards of quality and environmental sustainability in supermarkets is ever-increasing. Ensuring the preservation of food products, extending the lifespan of equipment, and securing efficient energy consumption are key priorities for supermarkets in Florida. Therefore, offering quality maintenance and technical support services is crucial—and even better when done in an automated way, utilizing the tools that technology provides to optimize solutions.

Development of Custom Software for Automated HVAC Solutions in Florida’s Supermarkets.

At Dynamiq, we’ve identified the need to offer highly specific solutions tailored to the most demanding technical challenges. That’s why we created a specialized department for the development of applications using robust, high-capacity PLC controllers designed to meet a wide range of needs. These include pump control, RTU units, chillers, lighting systems, motor control systems, VFDs, and web access. Our solutions also allow for integration with various protocols, ensuring greater flexibility and adaptability in any environment.

In this competitive business landscape, Dynamiq Automation Solutions is committed to developing innovative technologies and solutions for energy optimization. The company continues to grow its client base and expertise, proving its problem-solving abilities in energy management through the technical development, programming, and implementation of software for HVAC systems.

Dynamic Solutions to Optimize HVAC Systems in Florida Supermarkets

At Dynamiq, we are fully aware of these needs. That’s why we have been working on building the capacity to design software that meets our clients’ demands. The new Department of Technological Development and Innovation is already showing promising results, and the company continues to pursue its ambitious goal of positioning itself as a leader in the competitive Florida market. 🏆

Developing proprietary software to customize the HVAC systems of our clients offers numerous advantages. Supermarkets, as our main customers, require a highly specialized approach due to the critical need to keep their refrigeration systems running without interruptions. Our software automatically schedules preventive maintenance, manages real-time alarms and faults, and prioritizes emergency situations. This ensures the protection of perishable products while enabling remote temperature control and equipment monitoring. All these functions are focused on solving issues before they impact business operations.

Among the standout features of our controllers are:

- Flexible I/Os

- Modular concept (connect up to 20 expansions)

- Auto-recognition function

- Universal I/Os

- Built-in stepper motor controller (Plus versions)

- Improved execution speed and memory

- Optimized CPU memory

- Scalable RAM and ROM

- Faster compile times, with reduced cycle time

- Wide selection of interfaces

- Quick-mount display (with copy function)

- LCD display option*

- Touchscreen displays*

- Security and reliability

- FailSafe function

- Isolated power supply

- High-precision I/Os

- Designed according to IEC 62443 cybersecurity guidelines

- Advanced connectivity

- 2 Ethernet ports

- USB-C

- 2 opto-isolated Modbus RS485

- CAN FD as a fieldbus for other controllers and remote user interfaces

Image of software.

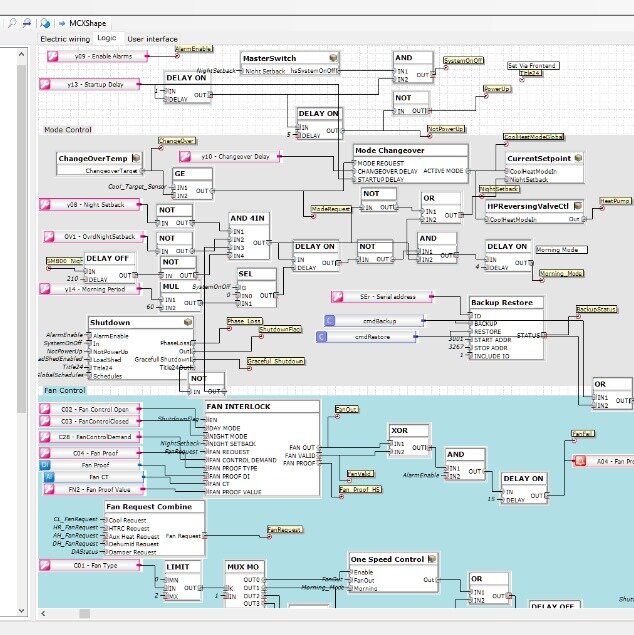

Software Development Phases

Our first proprietary software is currently in the simulation and testing phase. It has passed all verifications and will soon be ready for implementation with our clients. 🤝 Humberto Hervella Mateos, Developer and Head of the Department of Technological Development and Innovation, commented on the state of the software:

«We want to conduct some practical tests, install it on a controller, and test what we’ve programmed. For now, it’s only in the simulation phase. With the Design platform, you program what you need and upload it directly to the controller. Once programmed, it’s placed in the store for operation. This completely automates the refrigeration and climate control systems, including turning equipment on and off, constant temperature monitoring, and real-time control of all critical parameters. This optimizes operation, improves energy efficiency, and ensures precise and reliable control of every process.»

Danfoss, our supplier, has provided us with programmable MCX controllers, part of their extensive product range, which we are using to develop our solution. This has been made possible through our collaboration with Danfoss’ MCX Design platform, which has facilitated the creation and development of algorithms for programming the software. 🔍 Additionally, GalpaExport has played a key role in interacting with the Danfoss team, enabling the optimal use and application of the MCX controller in our project.

Danfoss MCX controlers

A Formula for Success

Oriesky Joya, CEO of Dynamiq, passionately advocates for every achievement of the Department of Technological Development and Innovation:

«We ourselves, based on the practical experiences of our work, design the logic on which the software operates. The programmed algorithms are focused on offering personalized solutions according to the needs of our clients. This software, still in the testing phase, is not only our first proprietary application but also an expression of our problem-solving capabilities in response to the current demands of HVAC systems.»

One of the main successes of this work has been how we’ve acquired and developed the capacity to create our personalized solutions. A team of engineers specializing in Automation, Electronics, Computer Science, and Telecommunications is working to optimize specific solutions for Florida supermarkets. Ensuring immediate responses to breakdowns, real-time temperature monitoring, and acting precisely in response to any incident are some of the key advantages our software offers.

The success of this project wouldn’t have been possible without the commitment and collaboration of the Dynamiq development team. Continuous research and the combined efforts of the engineers in the Department of Technological Development and Innovation have been crucial in advancing the creation of efficient, personalized technological solutions. Each developer has brought their expertise in automation, programming, and data analysis, ensuring that the software not only meets the highest standards but also adapts to the specific needs of our clients. This spirit of teamwork, grounded in research and innovation, enables Dynamiq to continue growing with its software for automated HVAC solutions in Florida’s competitive market.