The impact of our most recent work continues to resonate: the upcoming opening of Bravo Supermarket‘s new facility in Tampa. This achievement proudly demonstrates Dynamiq’s excellence in energy management and industrial maintenance services. Curious about our recipe for success? Read on to discover the details about leak check after pressure testing! Undoubtedly, this seemingly small but fundamental process plays a vital role in the integrity and optimal functioning of systems.

Following a pressure test to assess its resistance, we perform a leak test. It ensures that there are no leaks that compromise the safety or efficiency of the equipment.

Moreover, its importance lies in its ability to detect even the smallest leaks that might go unnoticed during the initial pressure test. In short, these leaks, if not detected and corrected in time, can lead to energy losses, reduced performance and, in extreme cases, safety hazards.

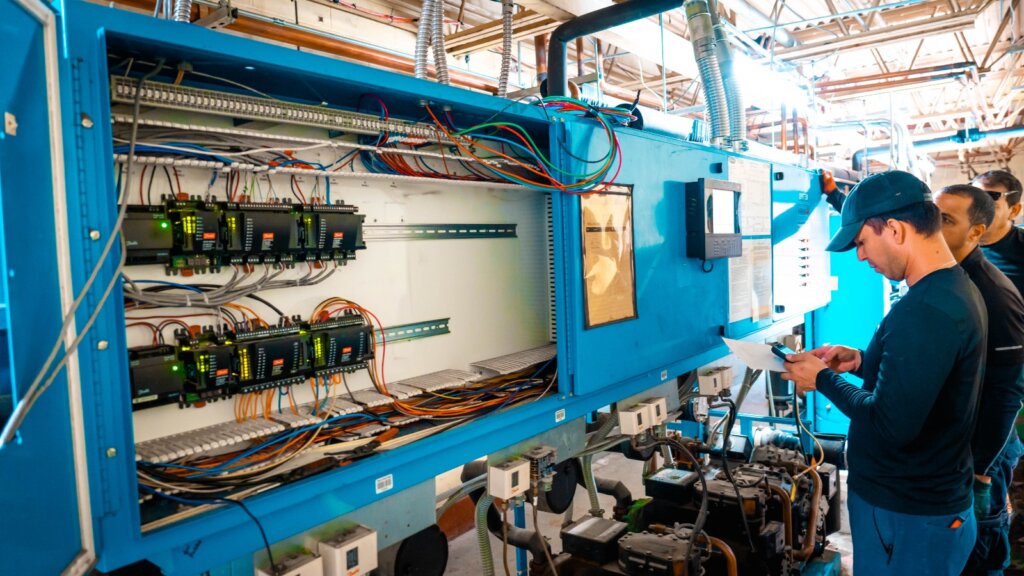

At Dynamiq Automation Solutions, we are dedicated to ensuring excellence at every stage of the project. In Bravo Supermarket’s latest installation, verifying the system’s tightness after operation is crucial. To achieve this, we performed a leak check after the pressure test. After completely evacuating the system, we apply a specific gas and conduct a thorough leak test using state-of-the-art equipment. This rigorous evaluation allows us to detect even the smallest leaks, ensuring complete system integrity. This step is essential to properly prepare the equipment for commissioning.

Our specialists receive rigorous training. They detect and correct irregularities to fully prepare equipment for commissioning and trouble-free start-up.

This meticulous approach and commitment to excellence are Dynamiq’s cornerstones, and we pride ourselves on delivering world-class services in energy management and industrial maintenance. We are committed to exceeding our customers’ expectations and ensuring the success of every project.